how does a cooling tower work with a chiller

An air cooled chiller absorbs heat from water and transfers it into the air and is used where discharge is not a problem. The main difference is that one uses air to fuel condenser cooling and the other uses water.

Wazipoint Engineering Science Technology How Economizer Works In Centrifugal Chiller Refrigeration And Air Conditioning Energy Saving Devices Save Energy

A chiller is a type of refrigeration system that cools a tub of glycol to reduce its temperature.

. A chiller works on the principle of vapor compression or vapor absorption. Using a total system approach every cooling tower and component is designed and engineered to work together as an integrated system for efficient performance and long life. Water cooled chillers are normally combined with a cooling tower and use a condenser water treatment system to remove mineral deposits.

Donomulio Industry Indonesia and Ebara Corporation Japan. HVAC Free Cooling A free cooling system allows the tower to directly satisfy a buildings cooling needs without the need of operating the chiller in cold weather. This is known as evaporative cooling.

Last time we talked about the impact that the wet bulb temperature has on cooling tower performance. This section will review each of the components. A water cooling tower receives warm water from a chiller.

The chilled water can either be used immediately or be stored for the short- or long-term. The first step in setting up a glycol cooling system is to establish a glycol chiller in a closed loop system. Piping condenser cooling tower losses and valves.

How Does a Chiller Work. HomePT Ebara Indonesia the first domestic manufacturer of water pumps in Indonesia was incorporated in 1980 in Jakarta in the form of joint venture between PT. Free cooling is an economical method of using low external air temperatures to assist in chilling water which can then be used for industrial processes or air conditioning systems.

The system consists of a chiller cooling tower building cooling load chilled water and condensing water pumps and piping. During most of the year the unit works as a conventional dry-cooler with no water consumption and the heat transported by the water is dissipated in the ambient air by convection of the air forced by the fans. A centrifugal chiller utilizes the vapor compression cycle to chill water and reject the heat collected from the chilled water plus the heat from the compressor to a second water loop cooled by a cooling tower.

The wetbulb method will provide good condenser relief for the chiller and cooling tower fan work relief when the chiller is not operating at 100 capacity. Thus the vapor becomes water again as the air pressure decreases. It can be a good balance between chiller and tower work.

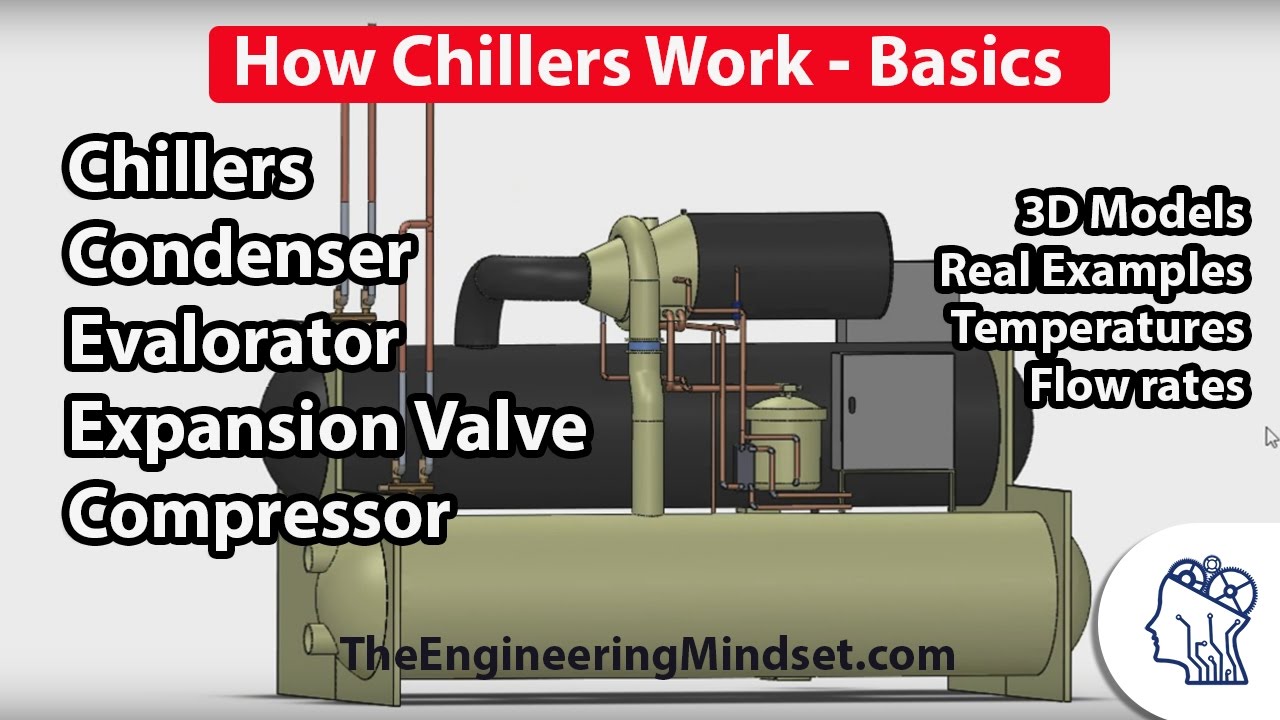

The higher the wet bulb the harder a cooling tower has to. It consists of the following four main components. It has 2 working modes.

These programs monitor the. Scroll to the bottom to watch the video tutorial on this subject The main system components of the. This is why glycol cooling systems are becoming more common than ever before.

The air cooled chiller condensers can be either dry air or evaporatively cooled. Supplyreturn temperatures from the chiller and cooling tower water flow rates from the condenser water. The cooling tower sends water to the chiller to be cooled.

A cooling tower is a large heat exchanger unit which provides cooling water to remove heat from a coolant which has been used to cool machinery process fluids or buildings. This warm water is known as condenser water because it gets heat in the condenser of the chiller. A water cooling tower is used to cool water and is a huge heat exchanger expelling building heat into the atmosphere and returning colder water to the chiller.

The cooling tower pipe has a lower air pressure than the condenser. Chiller Basics The chiller can be water cooled or air cooled. Chillers provide a continuous flow of coolant to the cold side of a process water system at a desired temperature of about 50F 10C.

It must also provide the energy head necessary to raise water from a low to a higher static head level. For the tower piping circuit the pump must overcome the piping flow friction loss. -All chillers require basic maintenance in order to perform at optimum levels but air cooled chillers are easier and less expensive to maintain than water-cooled units-Air cooled chillers do not require a cooling tower or a condenser water pump.

When the cooling water meets with air a small portion evaporates lowering its temperature. Ultimately the best cooling tower control designs are part of a chiller plant optimization program. How does a Chiller Cooling Tower and Air Handling Unit work together to provide air conditioning HVAC to a building.

The cold water then goes into the evaporator and waits to be mixed with the lithium bromide in the absorber again. How Does a Cooling Tower and Chiller Work Together. For large-scale cooling operations combining the two systems might be a.

In short the. Glycol Is Pumped Through A Closed Loop System. Figure 1 shows the basic centrifugal refrigeration circuit.

In summary its harder to evaporate water into air thats already wet. During high ambient temperature periods and only when the dry mode is not sufficient to maintain the outlet water. When outdoor temperatures are lower relative to indoor temperatures this system utilizes the cool outdoor air.

Then the vapor in the condenser on the top will go through a cooling tower. In this article we will be covering this topic to understand the basics of HVAC central plant. For small-scale applications such as chilling small rooms and exhausts of equipment you can use a suitably sized air-cooled or water-cooled chiller and a portable cooling tower installed on the roof of your building.

Yazaki Energy Water Fired Single Effect Chiller Application Refrigeration And Air Conditioning Water Cooling Energy System

Pin By Industrial Wastewater On Cooling Tower Water Treatment Water Conservation Cooling Tower Water Treatment

Timber Cooling Tower Cooling Tower Tower Tower Design

How Cooling Towers Work เคร องทำความเย น

What S The Difference Between Chillers And Cooling Towers Cooling Tower Tower Tower Fan

Cooling Tower Basics Calculation Formulas Cooling Tower Efficiency Cooling Tower Refrigeration And Air Conditioning Basic Concepts

Scy Water Cooled Portable Chiller Working Principle Water Cooler Water Chillers Water Supply

How Evaporative Cooling Towers Works Explained By Industry Leaders Cooling Tower Refrigeration And Air Conditioning Hvac Repair

Technical Equipment Of Buildings Drawing Hledat Googlem Commercial Hvac Hvac System Hvac Design

Chiller Diagram System Refrigeration And Air Conditioning Hvac Design Hvac Air Conditioning

Central Energy Plant Basic Overview How A Chiller And Cooling Tower Work Together Cooling Tower Hvac Air Conditioning Refrigeration And Air Conditioning

Diagram Showing The Components Of A Water Cooled Chiller Cooling Tower Shed Building Plans Chill

How A Chiller Cooling Tower And Air Handling Unit Work Together The Engineering Mindset Cooling Tower The Unit Tower

How A Chiller Cooling Tower And Ahu Work Together Hvac Air Conditioning Cooling Tower Tower

Central Energy Plant Basic Overview How A Chiller And Cooling Tower W Refrigeration And Air Conditioning Hvac Air Conditioning Air Conditioning Maintenance

Containerized Water Chiller System For Cooling Water Chillers Chill Room Chill

Pin By Hani Hazzam On Hvac Refrigeration And Air Conditioning Refrigeration And Air Conditioning Hvac Air Conditioning Cooling Tower

Chiller Types And Application Guide Chiller Basics Working Principle Youtube Refrigeration And Air Conditioning Air Cooling System Power Engineering

Central Energy Plant Basic Overview How A Chiller And Cooling Tower Work Hvac Air Conditioning Refrigeration And Air Conditioning Electrical Wiring Colours